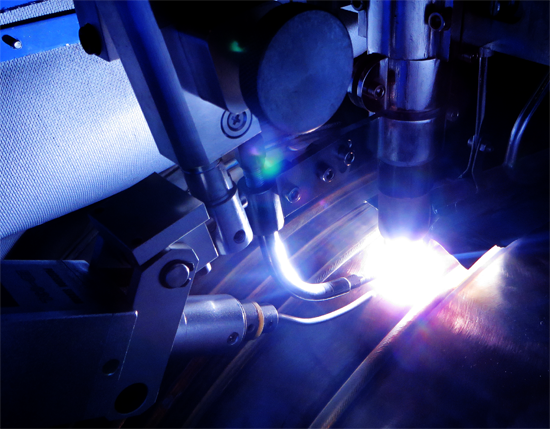

Getweld Automated Longitudinal Seam Welders (Open type, TIG or MIG) are designed for small to large-scale straight welding applications. These machines commonly function to weld seams at the outside surface of tanks.

Open type seam welders have features of high precision, easy loading and unloading, simple operation……

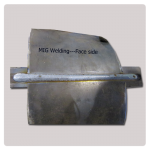

MIG welding is with high welding speed, 1000mm per minute. SS 304 below 4mm without opening groove could be full- penetration welded by one time. One side welding with double-side forming.

TIG welding has highlight advantages, such as smooth welding quality, one-time full-penetration welding for plate below 4mm without groove, easily controlled welding height, accordant width and height, Esp. for pulse TIG welding. Welding seam quality is perfect and more easily polished than that of MIG welding.

Automate Longitudinal Seam Welders (Open type, TIG or MIG) are normally used for stainless steel solar water heater inner tank, porcelain enamel tank, LNG cylinder and large capacity cryogenic storage tank and etc.