Rounding→ Welding→ Flanging→ Beading→Corrugating→ Leakage test for welding line→ Seaming→Leakage test.

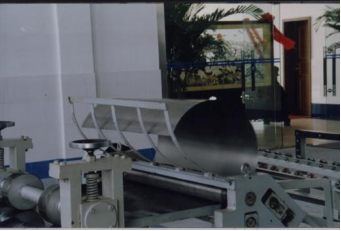

Semi-automatic welding machine

To connect the rounded drums body along the direction of the body, to weld by sewing welding machine, manual operate.We also have automatic type.

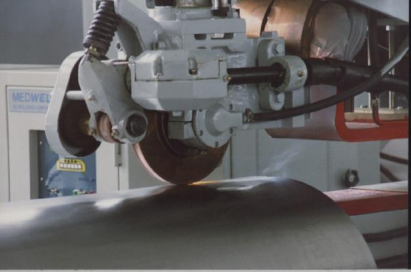

Automatic welding machine

Flanging and beading machine

The machine put the drum body to insert the forming mold plate, move front and back together to form the flange directly;At same time making the beading. Flange precision is perfect, working more efficiency, it is proper to use for cold rolling steel plate, PLC control, hydraulic driving.

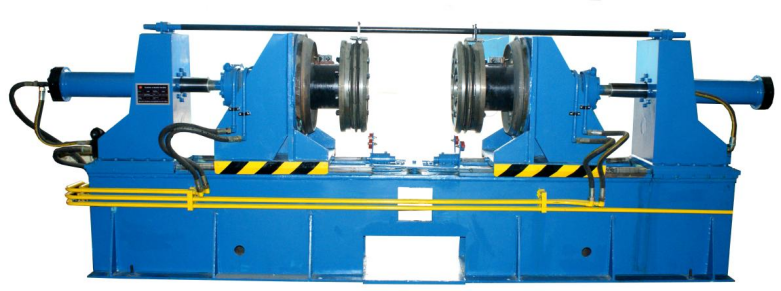

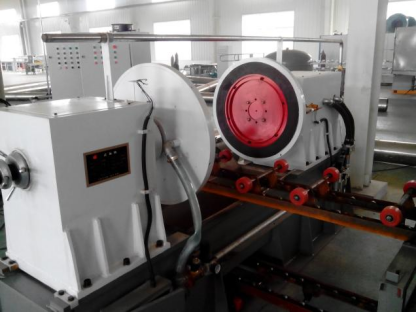

Corrugating machine

The machine makes the corrugate on the drums body from the two ends of drums body at the same time. Two rolls extend to the drum body inner and out at the same time to form the corrugate.The machine can make and press W type beading or corrugate, can make the W type beading and the corrugate at the same time, based on change the roll and wheel.

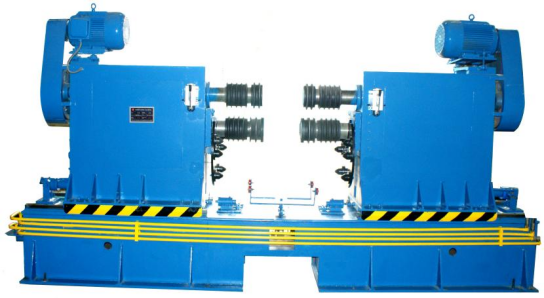

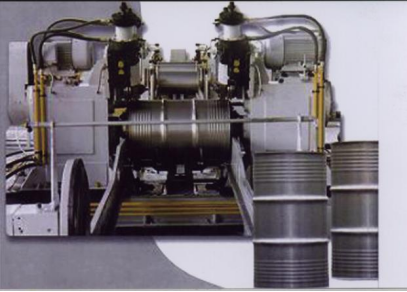

Seaming machine

one people put the drum top 、bottom lid on the lids auto-feeding machine , with drum body auto load press and seam the drums. Double motors and two main shafts running, this is new type construction in this field, cam mechanism drive the seam wheel up & down.

Leakage testing machine

Horizontal type test. Manual spray the soap water, manual tests the leakage.