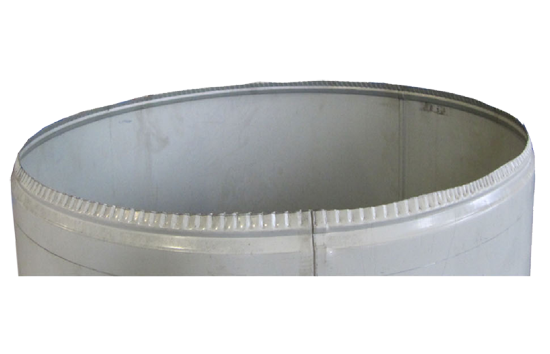

GetWeld Outer Tank Double-head Necking-in Machine is specially designed for forming of cylindrical tank body. Both open ends of tank could be shrinked with reinforced groove. With such shrinking, tank body connects with end dish just by hand press, without rivets, without welding. Machines have highlight advantages such as perfect quality, high productivity, simple operation, varies diameter. Manual type: Loading and unloading manually Semi-auto type: Loading automatically Allocates In cylinder and chain conveyer. Without manipulator and plate chain conveyer line Full-auto type: Loading and unloading automatically Allocates In cylinder, chain conveyer, 2 sets of manipulator and plate chain conveyer line.

Previous slide

Next slide

| Specification | |

|---|---|

| Features of machine | PLC control Touch type screen or button type screen Three types are optional, manual type, semi-auto type and full-auto type. One machine could process different dia. of tank. Tapered edge, easy for assembly Uniform shrinking edge with high strength |

| Application | GetWeld Outer Tank Double-head Necking-in Machines are designed for necking-in open ends of cylindrical working piece. A wide variety of materials can be processed, including galvanized steel, carton steel, carbon steel, aluminium, stainless steel…… |

| Material | Manual type: Loading and unloading manually Semi-auto type: Loading automatically Allocates In cylinder and chain conveyer. Without manipulator and plate chain conveyer line Full-auto type Loading and unloading automatically Galvanized steel Carbon steel Aluminium sheet Stainless steel Thickness of material: 0.3-0.6mm Solar water heater-Outer tank Porcelain enamel tank-Outer tank |

Fill out my online form.